Tailings are the left-over materials from the processing of mined ore. They consist of ground rock, unrecoverable and uneconomic metals, chemicals, organic matter and effluent from the process used to extract the desired products from the ore.

Tailings are stored in tailings storage facilities (TSFs). TSFs are dynamic structures that are designed and managed to contain the tailings produced by mining operations.

There are different types of TSFs:

- surface facilities, including paddock style or valley fills, can comprise multiple dams (or cells) that have continuous, structurally similar interconnected walls

- in–pit facilities

- dry stack facilities

How do TSFs differ from conventional water dams?

The principal difference between TSFs and conventional water dams is that TSFs are constructed to maintain storage of waste material produced during mining operations, whereas water dams are typically built to store and release water. Also, TSFs are dynamic structures that often grow over the life of the mine to accommodate increasing tailings volume whereas water dams are typically erected in a single phase of work. The construction materials can also differ. TSFs are usually constructed from earth and rock waste materials from the mine, whereas water dams can be constructed from earth, rock, concrete and other materials.

Tailing storage facilities

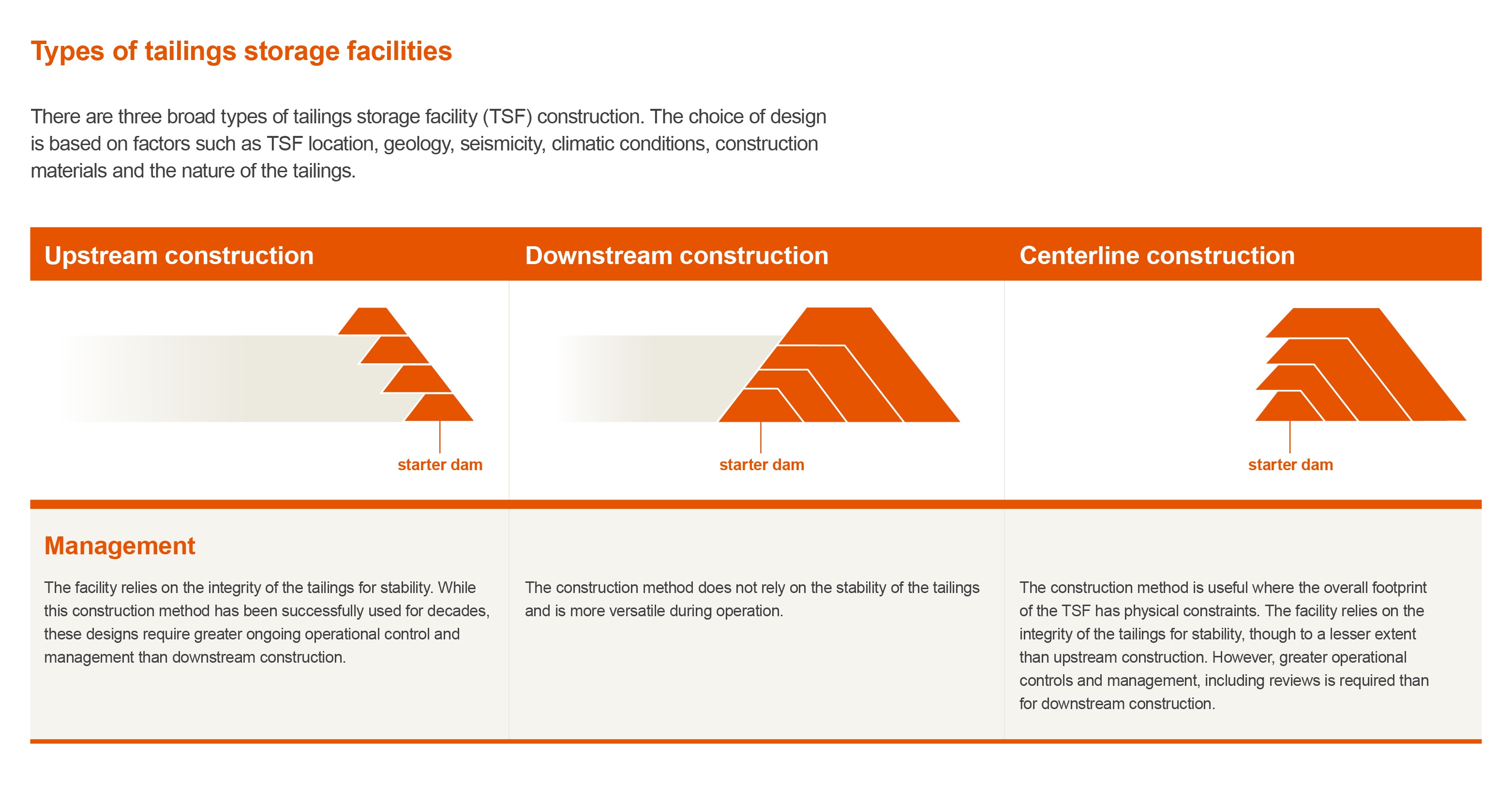

There are three broad types of TSF construction, which are depicted below. The design choice is based on factors, including:

- TSF location

- site conditions (geology, seismicity, climatic conditions)

- construction materials

- tailings characteristics

Maintaining TSF integrity requires ongoing focus on appropriate engineering design, quality construction, ongoing operating discipline, maintenance, effective governance and independent reviews. In addition to design choice factors, internal and external factors that can influence TSF integrity include:

- quality assurance and quality control of TSF construction

- maintaining TSF operating discipline, including tailings characteristics, water management, monitoring and consideration of changes to any of these factors

Life cycle of tailings storage facilities

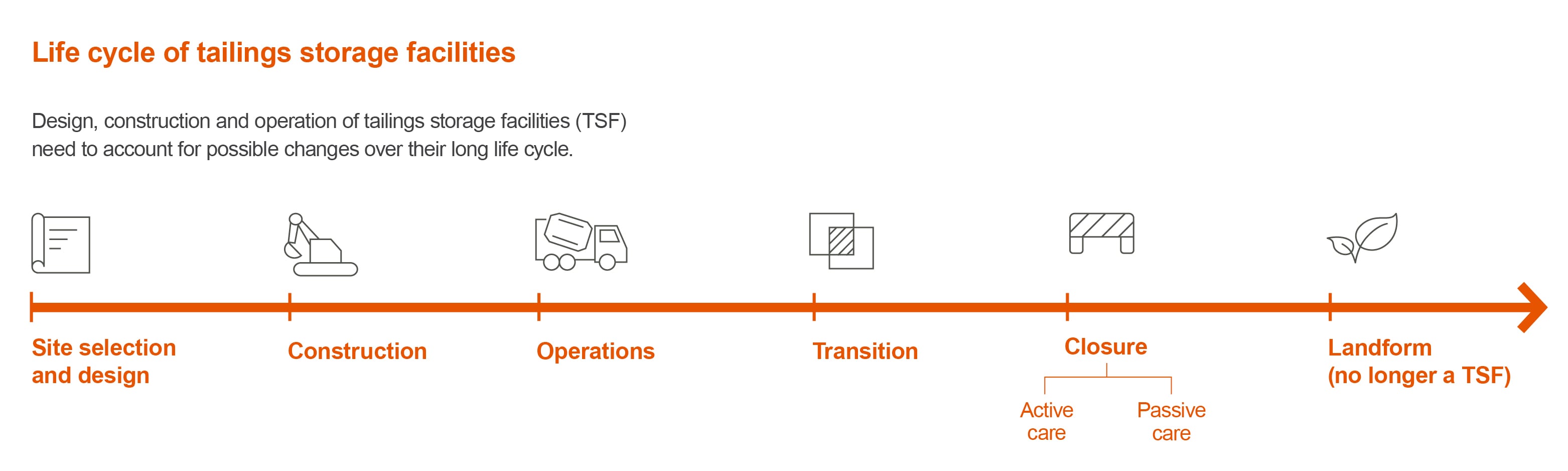

TSFs evolve over their life cycle, from planning, design, construction, operations, closure and ultimately to post closure. There may also be periods of care and maintenance between operational phases.

The duration of the closure phase in a TSF’s life cycle can exceed the duration of the operational phase. The closure phase may include transition from operations to active care when tailings deposition ceases. Active care typically includes a continuation of water, geochemical and physical management processes that are designed to maintain TSF integrity. Over time, inactive TSFs may transition to passive care when the ongoing water, geochemical and physical management requirements are reduced or eliminated. Once a TSF has transitioned to passive care, additional works may be carried out to rehabilitate the site, such as earthworks and re-vegetation.

Sustainability case studies, organisational boundary, definitions and disclaimers, and downloads

Prior year versions of some of the listed documents are available on the Past reports page.-

BHP Annual Report 2024

pdf

16192519

-

Sustainability reporting organisational boundary, definitions and disclaimers

pdf

161998

-

BHP ESG Standards and Databook 2024

xlsx

2555913

-

BHP Modern Slavery Statement 2024

pdf

4092160

-

BHP Climate Transition Action Plan 2024

pdf

8480121

-

BHP GHG Emissions Calculation Methodology 2024

pdf

1028031

-

CDP 2023 Submission Not Graded

pdf

1053064

-

Global Industry Standard on Tailings Management – Public Disclosure 2024

pdf

2809793

-

Tailings Storage Facility Policy Statement 2023

pdf

73457

-

Information for social investment partners

pdf

26113

-

Industry response to SBTI scope 3 discussion paper

-

Case studies