We focus on the safety and integrity of tailings storage facilities (TSFs) across our assets to protect people, the environment and communities where we operate.

Our ambition

At BHP, our purpose is to bring people and resources together to build a better world. One way we do this is by focusing on the safety and integrity of all TSFs across our operated and closed assets to protect people, the environment and communities where we operate.

Our approach and position

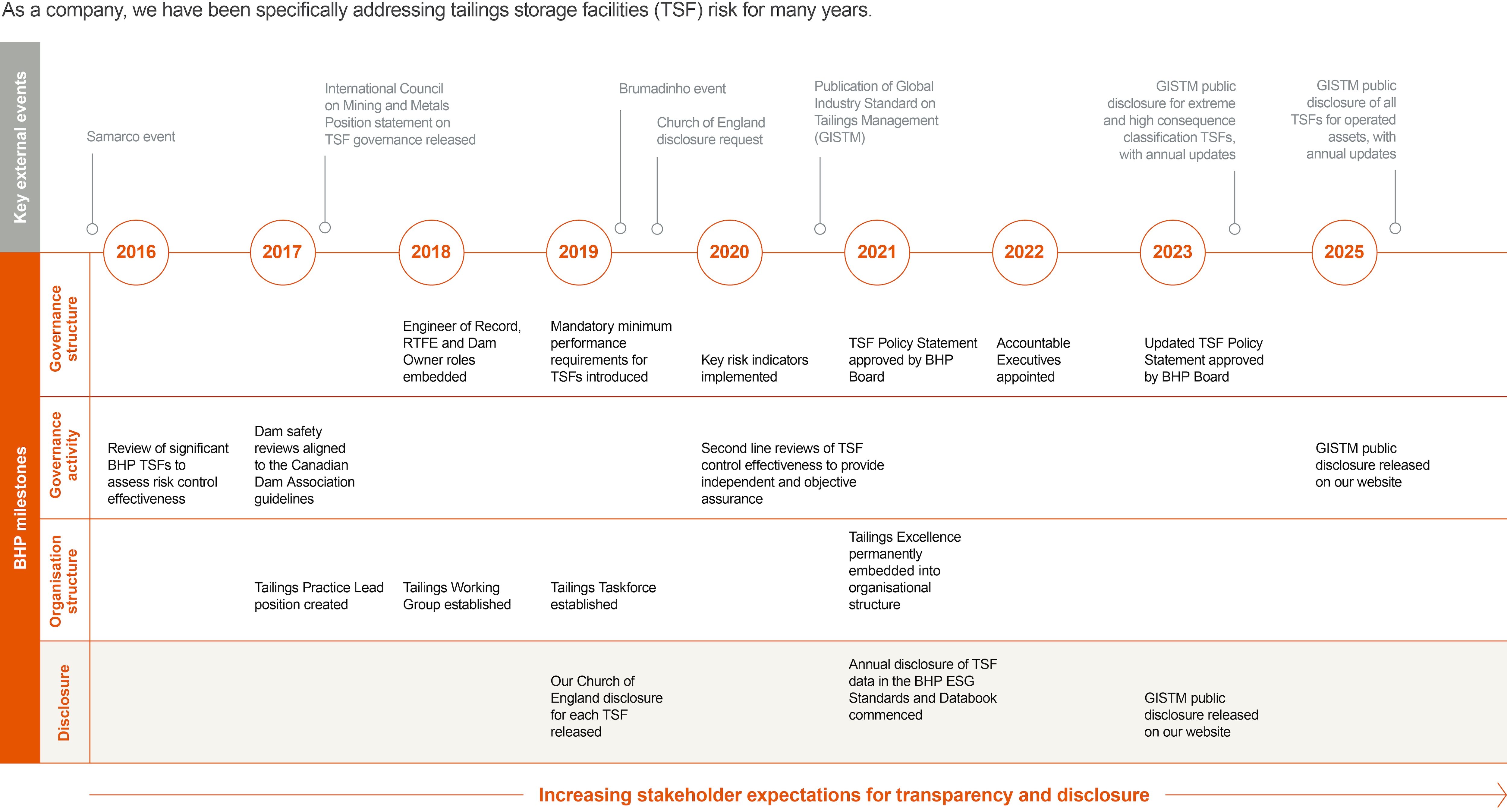

Following the tragic TSF failures at Fundão dam at Samarco in 2015 (a non-operated joint venture (NOJV) owned 50 per cent by BHP) and Brumadinho dam at Vale’s iron ore operation in Brazil in 2019, we continue to evolve our approach to TSF management, with a focus on the governance and conformance with industry standards, and the delivery of a continuous reduction in TSF failure risk.

Our tailings storage facility management evolution

Our short-term strategy focuses on improvement of key risk indicator performance, including studies to reduce and mitigate potential downstream impacts, particularly to those who could be at risk in the event of a TSF failure. Our medium- and long-term strategies focus on complex risk reduction projects and the identification and use of improved tailings management and storage solutions. Where there is a requirement to increase the current tailings storage capacity or construct a new TSF, we investigate cost-effective tailings management solutions, including non-conventional tailings solutions, as part of our efforts to reduce potential risks (aligned to our risk appetite) and increase social value. We are committed to achieving alignment with tailings industry standards, including the Global Industry Standard on Tailings Management (GISTM) and Towards Sustainable Mining (TSM).

For information on tailings and TSFs refer to the What are tailings and TSFs webpage.

Global Industry Standard on Tailings Management

We are committed to achieving alignment with the global benchmark for social, environmental and technical outcomes described within the GISTM for all operated TSFs. We support detailed, transparent and integrated disclosure regarding TSF management, publishing a GISTM public disclosure document on our website for all TSFs in alignment with the GISTM, supported by our ESG Standards and Databook. We have engaged a third-party contractor to progressively validate GISTM conformance aligned to the ICMM recommended timeframes.

As of August 2025, 61 of BHP’s TSFs are aligned with GISTM, with the remaining nine are working towards alignment. Of the partially aligned TSFs, one TSF is classified as very high consequence,1 three TSFs are classified as high consequence and the remainder are classified as significant or low consequence. We have received third-party validation of our alignment for 22 TSFs, representing 92 per cent of our very high and extreme consequence classification TSFs. The remainder of the aligned TSFs are based on BHP’s assessment of GISTM alignment. These TSFs will be validated by a third party in line with ICMM recommended timeframes.

The classification of a TSF as partially aligned with GISTM is not a statement on that TSF’s risk or safety, but rather an assessment on the TSF’s conformance to the GISTM. BHP’s governance and risk management frameworks are in place across our operated sites and manage TSF safety and integrity. The GISTM public disclosure document details the work required and timeframe to achieve alignment for those TSFs that are currently only partially aligned.

Footnote:

1. This TSF’s classification increased to extreme during FY2025. Information on the basis of the current classification, along with general information on consequence classification is available in the 2025 GISTM Public Disclosure.

Progress in FY2025

In FY2025, we continued works aimed at reducing our TSF failure risk, for example:

- The construction of a buttress was substantially completed at legacy asset’s Solitude TSF.

- We validated conformance with the GISTM at 12 of our extreme and very high consequence classification operated TSFs.

- We continued to progress alignment with the GISTM for the remaining TSFs at our operated and closed assets.

For more information on our TSF portfolio refer to Operated and non-operated tailings portfolio in the Other section below.

-

Governance and oversightFor information on the role of the BHP Board in overseeing our approach to and delivery on sustainability refer to the Sustainability approach webpage.

Our approach to TSF management focuses on strong governance and effective risk management. Our BHP Tailings Storage Facility Policy Statement outlines our commitment to the safe management of TSFs and our approach to governance and risk management, transparency, emergency preparedness, response and recovery in the event of a failure.

Our tailings storage facilities standard governs how we manage TSFs across our assets. The standard describes specific governance roles associated with the safe management of TSFs, including Accountable Executives who are direct reports of the CEO and communicate with the Sustainability Committee on matters related to TSFs. The standard also requires us to implement a management system that meets all the requirements of the six GISTM topic areas and additional BHP-specific requirements, including independent assurance across the entirety of the mine lifecycle.

The Tailings Excellence team supports our assets with continual improvement, risk management and assurance of our operated TSFs, progressing the development of technology to improve tailings management storage and working towards alignment with the GISTM. -

Engagement

Actively engaging with our stakeholders regarding our TSFs is a priority. This includes other industry participants that we are working with in our ongoing effort to realise positive outcomes at BHP and across the industry.

Industry participation

We have contributed to improvements in tailings storage management across the mining industry, including through the ICMM Tailings Working Group. We are participants in other tailings working groups globally, including those associated with the Canadian Dam Association, Australian National Committee on Large Dams, Australasian Institute of Mining and Metallurgy, Minerals Council of Australia, Mining Association of Canada, Society for Mining, and Metallurgy and Exploration.

We have formed a collaboration agreement with Rio Tinto to accelerate the development of technology that could significantly increase water recovery from mine tailings, and in turn, reduce potential safety risks and environmental footprints associated with TSFs.

In conjunction with Rio Tinto and the University of Western Australia, we have developed Future Tails, an initiative focused on training, education, research and best practice guides in the tailings management space. For more information refer to the Future Tails case study.

-

DisclosureWe commit to detailed, transparent and integrated disclosure regarding TSF management. We continue to work with industry to support the development of disclosure standards and improvements for tailings storage management across the mining industry, including through the ICMM Tailings Working Group and our support of the Investor Mining and Tailings Safety Initiative. We also engage with the community, regulatory and financial stakeholders and promote the application of consistent disclosure that informs better tailings stewardship.

We publish and regularly update our information and commitment to safe TSF management on our website and annually in our ESG Standards and Databook and GISTM public disclosure. -

Other

Operated and non-operated tailings portfolio

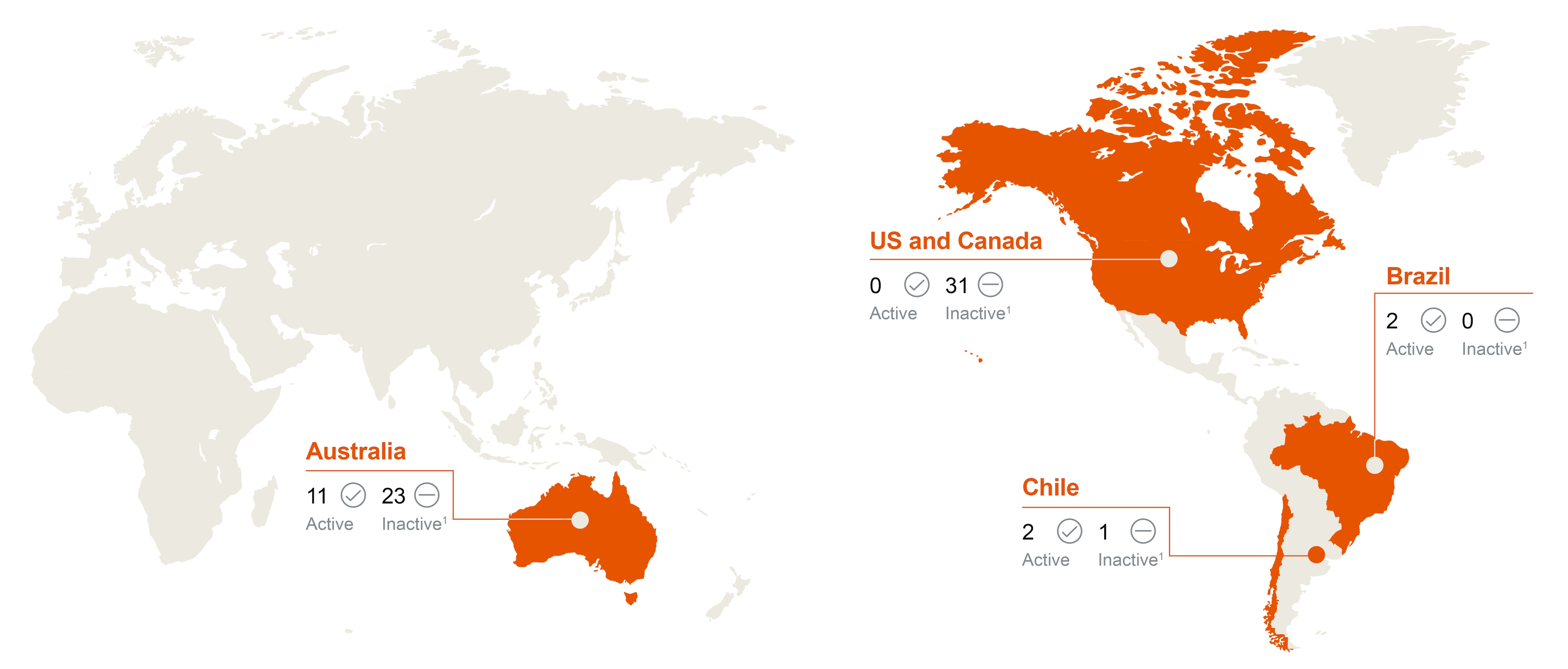

BHP has 70 TSFs at our operated assets. In addition, there are 10 TSFs at our NOJVs, which are all located in the Americas.

Location and operational status of operated tailings storage facilities

Footnote:

1. ‘Inactive’ includes tailings storage facilities in construction, not in operational use, under reclamation, reclaimed, closed and/or post-closure care and maintenance.

Risk

We operate to a single Risk Framework for all risks, including TSF failure risks at our assets. We use key risk indicators, set by senior management, to help monitor performance against BHP’s risk appetite. Our Risk Framework requires the pursuit of risk reduction actions to eliminate or reduce exposure to TSF failure risks until they are within BHP’s risk appetite.

Our approach to TSF risk management is detailed in Tailings storage facilities risk management.

For more information on our Risk Framework, which we operate to for all risks (including TSF risk), refer to our BHP Annual Report 2025, Operating and Financial Review 7 – How we manage risk.

Case studies

Sustainability case studies, organisational boundary, definitions and disclaimers, and downloads

Prior year versions of some of the listed documents are available on the Past reports page.-

BHP Annual Report 2025

pdf

17068205

-

Sustainability reporting organisational boundary, definitions and disclaimers

pdf

170075

-

Límite organizativo de los informes de sostenibilidad, definiciones y descargos de responsabilidad

pdf

234993

-

BHP ESG Standards and Databook 2025

xlsx

2541694

-

BHP Group Modern Slavery Statement 2025

pdf

7308735

-

BHP GHG Emissions Calculation Methodology 2025

pdf

1124687

-

BHP Climate Transition Action Plan 2024, subject to updates of certain aspects of our assumptions and plans in the BHP Annual Report 2025, Operating and Financial Review 9.8 – Climate change

pdf

8480121

-

Global Industry Standard on Tailings Management - Public Disclosure 2025

pdf

25537144

-

Tailings Storage Facility Policy Statement 2023

pdf

73457

-

Case studies