We recognise the interconnectivity of nature, climate and people and the risks posed by the unprecedented global deterioration of nature, including biodiversity. BHP’s business, our suppliers and customers, Indigenous peoples and the local communities where we operate, all depend on and enjoy nature and the ecosystem services it provides. We understand that our operations and our environmental performance can impact the natural environment, including the provision of ecosystem services.

We support the recommendations of the Taskforce on Nature-related Financial Disclosures (TNFD) and will continue to progressively evolve our disclosures in consideration of them.

Our ambition

Our vision is to contribute towards global efforts to halt and reverse nature loss and collective goals on nature and climate change to support business resilience and social value.1

Our 2030 Healthy environment goal is to create nature-positive2 outcomes by having at least 30 per cent of the land and water we steward3 under conservation, restoration or regenerative practices. In doing so we focus on areas of highest ecosystem value both within and outside our own operational footprint, in partnership with Indigenous peoples and local communities.

Our approach and position

We recognise that to help enable the energy transition, support a growing population that is becoming increasingly urbanised, and to improve standards of living, minerals production will need to increase. It is essential this production meets high standards of environmental stewardship.

We also recognise our performance in managing environmental impacts to the land, water and air where we operate may impact Indigenous peoples and local communities.

We seek to avoid or minimise adverse environmental impacts through every stage of our operational activities and acknowledge our role in contributing more broadly to the resilience and productivity of the natural environment. This is in line with Our Values, Our Code of Conduct, key BHP position statements (e.g. the Water Stewardship Position Statement) and Group-wide standards (e.g. Environmental Global Standard and Climate Change Global Standard).

Our Group-wide approach to environmental management is set out in the Environment Global Standard, which is applicable to BHP’s operated assets. The Standard details our mandatory minimum performance requirements to deliver on our environmental-related commitments, which include those in the Our environmental-related commitments table below, and manage our environmental risks, using management systems aligned to ISO14001. These standards require us to take an integrated, risk-based approach to managing any actual or reasonably foreseeable impacts (direct, indirect and cumulative) and dependencies on biodiversity, land, water and air. We establish and implement monitoring and review practices designed to ensure continued management of environment-related risk within our risk appetite through business planning and project evaluation cycles. Our Environment Global Standard (alongside our Climate Change Global Standard) also helps support the achievement of our goals, targets and commitments.

More specifically, our approach to environmental management is based on and influenced by:

- the identification, assessment and management of risks (threats and opportunities, impacts and dependencies) across all phases of our operational life cycle, including exploration, development, operation, closure and post-closure. BHP applies a Group-wide Risk Framework to identify and manage risks, including environmental risks

- engagement with internal and external stakeholders to ensure we take their perspectives and knowledge into account in our decision-making

- the realms of nature (land, oceans, freshwater and atmosphere) that we may impact or depend on

- the five key drivers of nature loss (changes in land and sea use, direct exploitation of natural resources, climate change, pollution, invasive species), as outlined by the Intergovernmental Science-Policy Platform on Biodiversity and Ecosystem Services

- the extent and nature of our planned activities and optimising our activities to seek to minimise or prevent adverse impact and maximise contribution to social value

- societal risks, such as habitat loss and pollution

We use our Environmental Management System (EMS) to implement our approach to environmental management, as well as drive continuous improvement in our environmental performance. The Environment Global Standard mandates the use of an EMS that aligns with the global environmental management framework ISO 14001. We seek to continually refine our internal decision-making, risk management and reporting systems and processes to strengthen the environmental performance of our operations, and to manage risks (threats and opportunities) from our impacts and dependencies on nature.

We also set targets and goals to guide our stewardship of nature, including contributing to global efforts to halt and reverse nature loss through our 2030 Healthy environment goal, helping to address the water challenges shared by BHP and other stakeholders in the regions where we operate through our context-based water targets, and supporting efforts to mitigate climate change through our greenhouse gas emissions targets and goals. Through our Group-level biodiversity strategy, Water Stewardship Position Statement and Climate Transition Action Plan 2024 (subject to updates of certain aspects of our assumptions and plans in the BHP Annual Report 2025, Operating and Financial Review 9.8 – Climate change), we outline our vision, strategies and focus areas to support action on these global challenges.

Beyond our BHP footprint, we make voluntary contributions in support of environmental resilience across the regions where we operate through social investment, on-ground action and thought-leadership. Examples are provided in the case studies below, and those on the Water webpage and Biodiversity and land webpage.

Specific information about our water, climate and biodiversity approach and position can be found at the Water webpage, Biodiversity and land webpage and Climate change webpages. For more information on BHP’s 2030 goals, refer to the BHP Annual Report 2025, Operating and Financial Review 9.4 – 2030 goals. For more information on BHP’s Risk Framework refer to the BHP Annual Report 2025, Operating and Financial Review 7 – How we manage risk and Sustainability-related Risk Management webpage.

Mitigation hierarchy

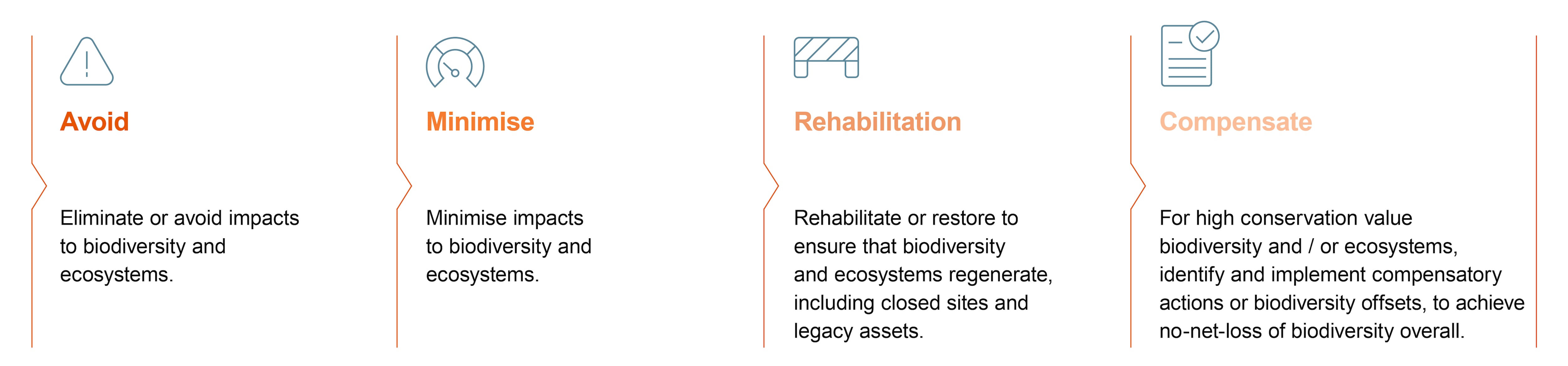

Our primary approach to preventing or minimising our potential adverse impacts to biodiversity and ecosystems within our operational footprint is to apply the mitigation hierarchy (avoid, minimise, rehabilitate and/or apply compensatory actions). This approach allows us to, if necessary, minimise and rehabilitate any unavoidable impacts to biodiversity and ecosystems. If actual or reasonably foreseeable residual impacts remain to high conservation value biodiversity and/or ecosystems after application of the first three priorities of the mitigation hierarchy, we apply compensatory actions by seeking conservation gains of the same value to achieve no-net-loss to biodiversity overall.

As detailed in the Environment Global Standard, our operated assets are required to identify and assess environment-related risks (threats and opportunities) and put controls and plans in place to manage these risks, in accordance with BHP’s Risk Framework. This includes the application of our frameworks, policies and processes, including governance, assurance and risk management.

Our Healthy environment goal

We have set and are now focusing on the steps required to achieve our 2030 Healthy environment goal to contribute towards global efforts to halt and reverse nature loss.

Our 2030 Healthy environment goal is to create nature-positive2 outcomes by having at least 30 per cent of the land and water we steward3 under conservation, restoration or regenerative practices. In doing so we focus on areas of highest ecosystem value both within and outside our own operational footprint, in partnership with Indigenous peoples and local communities. We focus our activities in support of achieving this goal on the large areas of non-operational land we steward, as this land offers an opportunity for us to apply conservation, restoration or regenerative practices at a larger scale.

The key metrics to track progress on delivery of the 2030 Healthy environment goal are the:

- area under nature-positive management practices4

- number of our operated assets with a natural capital account5

A breakdown of area under conservation, restoration or regenerative management practice can be found in the BHP ESG Standards and Databook 2025.

Our 2030 Healthy environment goal is supported by successive short-term milestones. We completed our initial FY2023 short-term milestones to undertake preliminary global mapping of important biodiversity and/or ecosystems (IBE) for operated assets in Minerals Australia and Minerals Americas, and to publish context-based water targets (CBWTs). More information can be found at our Biodiversity and land webpage, our IBE mapping case study, and our Shared water challenges webpage.

For the FY2024 short-term milestone, we developed a BHP Healthy environment goal roadmap which identifies opportunity areas where conservation, restoration and/or regenerative practices could be applied. Projects will be progressively selected from the BHP Healthy environment goal roadmap, planned and executed, to enable achievement of our goal. The roadmap was developed using a targeted version of the LEAP approach – an integrated approach developed by the TNFD to help organisations identify and assess nature-related dependencies, impacts, risks and opportunities. We used this approach to prioritise non-operational areas for conservation, restoration and/or regenerative activity on the basis of highest ecosystem value. This was done as follows:

- Locate your interface with nature: We mapped our land owned/managed/leased and our interface with sensitive locations using global datasets in our IBE layer.

- Evaluate your dependencies and impacts on nature: We identified environmental assets and ecosystem services using global datasets on natural and modified habitats, nature’s contribution to people and above/below ground biomass in our IBE layer.

- Assess your nature-related risks and opportunities: We prioritise opportunities for conservation, restoration and/or regenerative activity on the basis of highest ecosystem value as determined in our IBE layer. We consider risk to project permanence by prioritising areas outside of mining leases – also recognising that these non-operational areas present the greatest opportunities in terms of scale.

- Prepare to respond to and report on material nature-related issues: We have key metrics and annual milestones to track progress towards delivery of our Healthy environment goal and plan to consider effectiveness through a set of nature-related metrics that have been peer reviewed by CSIRO. For information on work we are undertaking to value, measure and monitor natural capital, including as part of projects under our Healthy environment goal, refer to the Biodiversity and land webpage.

Key progress against our Healthy environment goal is outlined below. For more information on our FY2025 progress on our natural capital metrics framework refer to our Biodiversity and land webpage and our natural capital accounting case study.

We are continuing to select projects from our BHP Healthy environment goal roadmap for detailed execution planning and seeking opportunities to design and advance projects in partnerships with Indigenous peoples. We are also monitoring the evolving external nature landscape, including developments in nature frameworks, standards and methodologies and in definition of the global nature ambition. We are exploring ways to respond to these emerging insights in our approach to our Healthy environment goal.

Footnotes

1 Such as relevant United Nations Sustainable Development Goals and international agreements such as the Kunming Montreal Global Biodiversity Framework.

2 Nature-positive is defined by the TNFD Glossary version 1.0 as ‘A high-level goal and concept describing a future state of nature (e.g. biodiversity, ecosystem services and natural capital) which is greater than the current state’. We understand it to include land and water management practices that halt and reverse nature loss – that is, supporting healthy, functioning ecosystems. We are monitoring the evolving external nature landscape, including developments in nature frameworks, standards and methodologies and in definition of the global nature ambition.

3 Excluding areas we hold under greenfield exploration licences (or equivalent tenements), which are outside the area of influence of our existing mine operations. 30 per cent will be calculated based on the areas of land and water that we steward at the end of FY2030. For more information refer to the BHP ESG Standards and Databook 2025.

4 Area under stewardship that has a formal management plan that includes conservation, restoration or regenerative practices. For more information refer to the BHP ESG Standards and Databook 2025.

5 Natural capital accounts are a way to measure the amount, condition and value of environmental assets in a given area. They help describe changes in ecosystems and how these impact wellbeing and economies.

Governance, engagement, disclosure and performance

-

Governance and oversight

-

Engagement

-

Disclosure

-

Performance

For information on the role of the BHP Board in overseeing our approach to and delivery on sustainability refer to the Sustainability approach webpage.

We have a range of core business processes, requirements and guidance materials that apply to our management of the environment at Group and operated asset levels. These include:

- our corporate planning, scenario, strategy and investment evaluation processes

- standards, such as the mandatory minimum performance requirements, including those on risk management, environment and climate change, closure, water, tailings, data, human rights, community and stakeholder engagement

- target and goal setting, for example our 2030 goals

- water accounting

- technical standards

- audit and assurance

|

Existing process

|

Application to environment |

|

BHP Board and Committees |

The BHP Board has oversight of our approach to and delivery on sustainability and is supported by each of its Committees. For more information refer to the Sustainability approach webpage.

|

|

Planning BHP has a corporate alignment planning process in place designed to implement the long-term Group strategy. The corporate alignment planning process guides the development of plans, targets and budgets to deploy capital and resources.

|

The planning process seeks to deliver an understanding of our projected production levels, land and water requirements, and emissions over decades. Risks (threats and opportunities) are required to be identified and assessed against social, environmental and economic considerations. For example, for some operated assets, access to ore is dependent on effective water management. Therefore, water is integral to short-term and life of asset plans, as well as production targets and effective environmental management. |

|

Strategy BHP assesses how divergent policy, technology, market and societal outcomes could impact our current portfolio.

|

We undertake ongoing monitoring of the macro economic, social and political environment that informs periodic re-assessment of the resilience of our portfolio because we recognise the world could respond in a number of different ways. |

|

Investment evaluation BHP has a Capital Allocation Framework that is designed to maximise shareholder value.

|

Our investment evaluation process assesses projects on a range of financial and other metrics, which incorporate social value metrics. We utilise our non-economically quantifiable impact (NEQI) framework to systematically identify, consistently evaluate and transparently present actual and potential social value impacts for consideration in our investment decisions where applicable. Our Water Stewardship and Biodiversity strategies include an assessment of the adequacy of the NEQI framework. |

|

Tailings storage facilities We are committed to achieving alignment with the global benchmark for social, environmental and technical outcomes described within the Global Industry Standard on Tailings Management for all BHP-operated tailings storage facilities (TSF).

|

When a new TSF is required, selection and design are integral to ensuring dam integrity. The TSF type and location are selected to minimise impact to people, the environment, infrastructure and community. For more information refer to the Tailings storage facilities webpage.

|

|

Global Standards BHP has a number of Global Standards that outline Group-wide mandatory minimum performance requirements. They are supported by technical standards and guidance documents.

|

The Environment Global Standard, the Climate Change Global Standard, the Closure and Legacy Management Global Standard and our internal water management standard are key documents that set mandatory minimum performance requirements for environment and water management and outline Group-wide and operational-level requirements.

|

|

Risk management At BHP, management of risk is central to protecting and creating long-term value. Our mandatory minimum performance requirements for risk management form part of our Risk Framework and outline BHP’s risk process that includes steps for risk identification, assessment, treatment, monitoring and review, and communication, including specific requirements for material risks. Risks are subject to internal and, in some cases, external evaluation of effectiveness of controls.

|

Environmental performance and nature-related risks, including biodiversity-, land-, water- and air- related risks, are required to be identified, assessed and managed in line with BHP’s Risk Framework, as outlined in the BHP Annual Report 2025, Operating and Financial Review 7 – How we manage risk. BHP uses the ‘three lines model’ to define the role of different teams across the organisation in managing risk, including environment-related risk. This approach sets clear accountabilities for risk management and provides appropriate checks and balances to support us in protecting and growing value. |

|

Environmental management The Environment Global Standard and the Climate Change Global Standard take a risk-based approach to managing a number of our environment and nature-related risks.

|

Our understanding of environmental performance and nature-related risks is increasing over time. BHP’s risk management processes assist in monitoring and assessing the implementation of approaches such as our Water Stewardship and Biodiversity strategies. For more information on our biodiversity and water-related risks refer to the Biodiversity and land webpage and the Water webpage.

|

|

Closure The Closure and Legacy Management Global Standard requires each operated asset to manage closure risks throughout the entire life cycle by considering social and environmental values, our obligations, safety, costs, risks (threats and opportunities) and the expectations of external stakeholders and partners, including Indigenous peoples.

|

All operated assets are required to follow the closure management process throughout their entire lifecycle. This requires the development of a closure management plan, designed to set objectives and achieve optimised closure outcomes, including nature-related aspects such as land, biodiversity, water, air and pollution. Closure outcomes must be developed in consideration of matters such as the expectations of external stakeholders and partners, including Indigenous peoples, our legal obligations and our public commitments. |

|

Human rights The Community and Indigenous Peoples Global Standard requires each operated asset to respect human rights and Indigenous peoples’ rights as set out in BHP's Human Rights Policy Statement and Indigenous Peoples Policy Statement. We aim to identify and manage potential human rights risks to local communities where we operate through our globally consistent methodology for conducting community and human rights impact and opportunity assessments (CHRIOAs) and integration with our Risk Framework.

|

The nature of our operations can have significant environmental impacts and those impacts can affect human rights. We require our operated assets to assess potential direct impacts on people, the interrelationship with other human rights, such as Indigenous, spiritual and culture rights, and specific implications for vulnerable and/or marginalised groups. Our Water Stewardship Position Statement recognises water access and sanitation as basic human rights. Our operated assets are required to identify and document potential human rights risks by undertaking human rights impact assessments. For more information refer to the BHP Annual Report 2025, Operating and Financial Review 9.11 – Community and the Human rights webpage. |

|

Community, Indigenous peoples and stakeholder engagement Understanding the needs and concerns of communities, Indigenous peoples and other stakeholders is fundamental to water stewardship and environmental management more broadly. The long-term nature of our operated assets means it is critical we make effective and genuine connections with people that can be sustained over time.

|

Our Water Stewardship Position Statement and Group-level biodiversity framework commits us to listening and learning from others to better understand and continuously improve our approach to water stewardship and biodiversity management, and to work with others to make progress towards delivering shared water, land and biodiversity challenges. For information on community and stakeholder engagement practices, refer to the BHP Annual Report 2025, Operating and Financial Review 9.11 – Community and 9.12 Indigenous peoples, our Indigenous Peoples Policy Statement, and our Community and Indigenous peoples webpages. For more information on water stewardship and biodiversity specific engagement refer to the Water webpage and Biodiversity and land webpage.

|

|

Climate change adaptation planning Our long-life operated assets require a robust, risk-based approach to adapting to potential physical climate-related impacts. Effective analysis of regional climate science is critical to inform our resilience planning at an operated asset level and improve our understanding of the climate-related physical risk impacts our operated assets may face.

|

Climate change may exacerbate risks related to water security, water scarcity and biodiversity loss. We have set mandatory minimum performance requirements in BHP’s Climate Change Global Standard and Environment Global Standard that our operated assets need to address to understand and manage climate-related risks. For more information on climate change adaptation planning refer to the BHP Annual Report 2025, Operating and Financial Review 9.8 – Climate and the Physical climate-related risk and adaptation webpage.

|

|

Audit and assurance Our Internal Audit team evaluates the design and effectiveness of our processes and management of material risk, including environment-related risks. These results are considered in the development of associated improvement plans. |

The Internal Audit team periodically undertakes a review of material environment-related risks, including air-, waste-, biodiversity- and water-related risk, and performance data to improve our understanding and consistency of approach to environmental management. The outcomes of internal audits are considered when updating environmental management systems, the Environment Global Standard, the Closure and Legacy Management Global Standard the Climate Change Global Standard and the internal water management standard, and are also considered by the Board and management when reviewing the Group’s material risk profile. |

BHP engages across communities, government, business and civil society with the aim of encouraging actions to improve natural resources governance and advance more sustainable solutions for the natural environment. We aim to do this through our individual actions, ongoing stakeholder engagement with local communities (refer to the Local communities webpage), as well as by promoting the adoption of industry best practice through industry and other associations we belong to, such as the International Council on Mining and Metals and the CEO Water Mandate.

We seek to attend or participate in key national and international collaboration forums (such as the Water in Mining Global Summit, the World Economic Forum Global Futures Council on Natural Capital, Proteus Partnership meetings, and BHP-led roundtables about nature-related issues and ESG investor briefings), as well as developing or continuing partnerships with NGOs and research organisations.

We monitor and disclose our Group performance on a range of nature-related indicators and metrics in line with external reporting frameworks, such as the Global Reporting Initiative (GRI), Sustainability Accounting Standards Board (SASB) and the ICMM Performance Expectations. For more information refer to the BHP Annual Report 2025, Operating and Financial Review – 9.2 Sustainability governance, the Sustainability approach webpage and the BHP ESG Standards and Databook 2025.

For more information on water-related disclosures, refer to the Water webpage. For more information on Biodiversity-related disclosures, refer to the Biodiversity and land webpage.

BHP supported the development of the TNFD framework as a TNFD Forum member and through our membership with the ICMM.

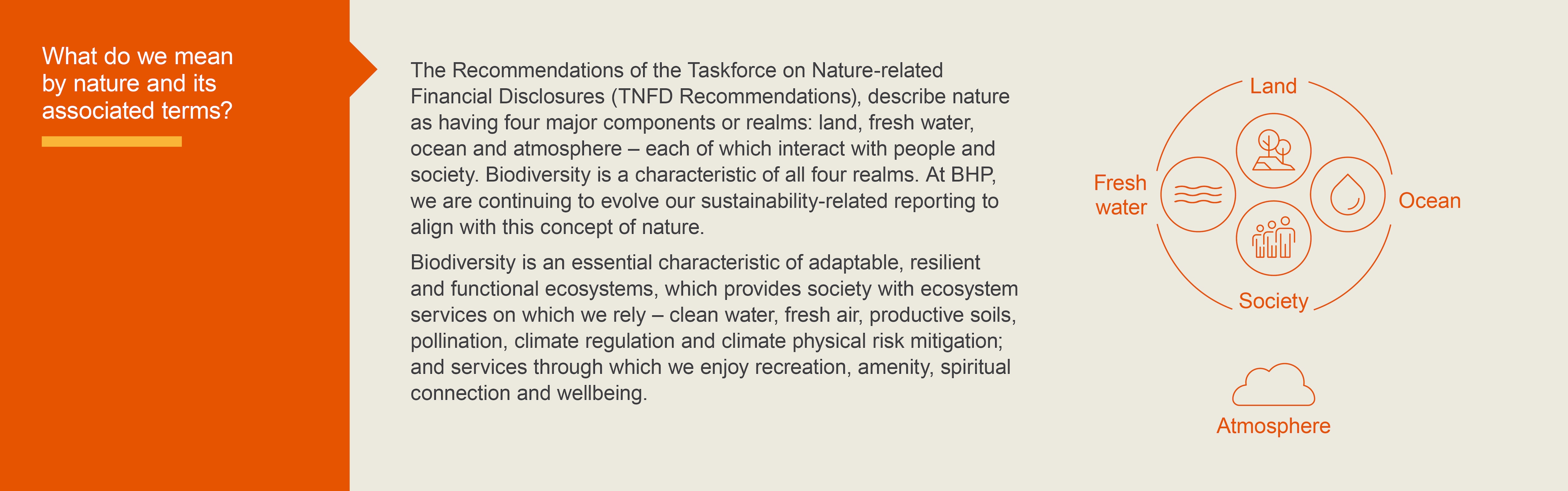

The TNFD Recommendations, finalised in September 2023, describe nature as having four major components or realms: land, fresh water, oceans and atmosphere – each of which interact with people and society. Biodiversity is a characteristic of all four realms. At BHP, we are continuing to evolve our sustainability reporting to align with this concept of nature.

Water and biodiversity are material topics for BHP, as evaluated by the GRI framework definition and process. For this reason, our specific disclosures on these topics are included on our Water and Biodiversity and land webpages and in the BHP Annual Report 2025, Operating and Financial Review 9.9 – Nature and environmental performance and our BHP ESG Standards and Databook 2025.

Air and waste performance information is set out below.

Air emissions

Clean air is crucial for the health of our people, our host communities and the surrounding ecosystems.

The most significant air emissions across our portfolio of operated assets relate to emissions of greenhouse gases (GHG) and dust. For information on GHG emissions, refer to the Climate change webpage.

We are improving how we manage air quality for particulate matter and gaseous emissions. Our programs use real-time monitoring, source sampling, incident tracking and risk-based assessments to better understand and control air quality impacts. Our Environment Global Standard requires an air quality management plan where a material risk of air quality related impact on community wellbeing or a sensitive environmental receptor is identified. The plan must consider a stakeholder engagement strategy, dispersion modelling, targets, objectives and reporting. Many of our sites have ongoing multi-year improvement initiatives to enhance long-term environmental performance on air quality. We report air emissions (including greenhouse gases and non-greenhouse gases) as part of the BHP ESG Standards and Databook 2025. In FY2025, we recorded a significant decrease in sulphur dioxide emissions following Western Australia Nickel going into temporary suspension.

Actions to improve dust management at our operated assets include:

- At Western Australia Iron Ore (WAIO), we announced plans in FY2020 to invest up to A$300 million over five years to improve air quality and reduce dust emissions across our Pilbara operations. For more information on the progress of the Pilbara air quality program refer to our case study.

- For the BHP Mitsubishi Alliance (BMA), we are developing an air quality framework for all operated mines, focusing on improving real-time air quality monitoring and dust management controls to contribute to proactive site operational measures.

- In Chile, we are implementing an air quality strategy for all our operated mines, focusing on real-time air quality and human health exposure monitoring, dust management control improvements, modelling and forecasting of air quality conditions and dust analytics.

Waste management

Resource extraction and processing can generate large amounts of waste. We are committed to continually improving our practices to minimise waste generation, increase recycling and repurposing of materials, and prevent pollution through proper disposal.

We broadly define waste from resource extraction into two main categories: mineral and non-mineral waste. These are further split into hazardous and non-hazardous streams, which are usually defined by local legislation.

Mineral waste includes waste from raw or intermediate materials, such as mineral ore that has been processed as part of the production sequence. We process some of our ores to increase the concentration of target minerals or remove unwanted components using processes such as beneficiation, refining and smelting. These processes generate mineral waste streams, such as tailings, waste rock, slimes, sludge, residues, slag, fly ash and gypsum or coal rejects.

Non-mineral waste includes waste that does not arise from minerals extraction and processing, but arises from our overall activities, such as packaging, lubricants, scrap metal and food waste from mining camps.

Mineral waste, including tailings, is the waste stream we focus on in our ESG Standards and Databook given it is the most significant waste for us in terms of the volume we generate. We also monitor and report hazardous waste streams (mineral and non-mineral), as required by local or national legislation.

While we focus on waste-related impacts related to our operations, we also recognise the potential downstream impacts of some of our products, for example uranium. Australian uranium is sold for nuclear power generation only and therefore waste associated with its use is disposed under specific local government regulation.

All waste streams (including waste from BHP operations that is managed by a third party) are required to be managed to the higher of applicable standards, such as the Environment Global Standard and tailings storage facilities standards, or the local legislative requirements.

We recognise the transition from traditional waste management approaches toward embracing the principles of a circular economy. One way we are putting this into practice is through our BMA Pit to Port Circularity Project. Learn more in the case study further below.

We also partner with others to advance the thinking in management of waste and pollution. For example, we contributed to the ICMM’s development of a ‘Tool for Acid Rock Drainage and Metal Leaching Prevention and Management’, which bridges the gap from the Internation Network for Acid Prevention’s Global Acid Rock Drainage Guide to provide a practical tool for site management of waters affected by mined materials.

We support and have contributed to the development of the Global Industry Standard on Tailings Management (GISTM), which was established as an international standard for safer tailings management through a process co-convened with the International Council on Mining and Metals (ICMM), United Nations Environmental Programme and the Principles of Responsible Investing. For information on our management of tailings storage facilities, including our GISTM public disclosure document, refer to the Tailings storage facilities webpage.

Risk

Our processes to identify, assess and manage environment-related risks are undertaken in line with BHP’s Risk Framework. For details refer to the BHP Annual Report 2025, Operating and Financial Review 7 – How we manage risk.

For information on water-related risks refer to the Water webpage.

Case studies

Regulatory information

We are committed to high ethical business practices and governance standards.

We provide detailed regulatory information in operational, environmental and community information for our local communities and key government stakeholders.

Sustainability case studies, organisational boundary, definitions and disclaimers, and downloads

Prior year versions of some of the listed documents are available on the Past reports page.-

BHP Annual Report 2025

pdf

17068205

-

Sustainability reporting organisational boundary, definitions and disclaimers

pdf

170075

-

Límite organizativo de los informes de sostenibilidad, definiciones y descargos de responsabilidad

pdf

234993

-

BHP ESG Standards and Databook 2025

xlsx

2541694

-

BHP Group Modern Slavery Statement 2025

pdf

7308735

-

BHP GHG Emissions Calculation Methodology 2025

pdf

1124687

-

BHP Climate Transition Action Plan 2024, subject to updates of certain aspects of our assumptions and plans in the BHP Annual Report 2025, Operating and Financial Review 9.8 – Climate change

pdf

8480121

-

Global Industry Standard on Tailings Management - Public Disclosure 2025

pdf

25537144

-

Tailings Storage Facility Policy Statement 2023

pdf

73457

-

Case studies