We recognise activities at our operated assets can impact the health of our people and the communities where we operate.

Our ambition

Our approach and position

Mandatory requirements to manage and protect the health and wellbeing of our employees and contractors are set out in the Health Global Standard and our mandatory minimum performance requirements for risk management, as well as local regulatory requirements, standards and procedures.

-

Governance and oversight

For information on the role of the BHP Board in overseeing our approach to and delivery on sustainability refer to the Sustainability approach webpage.

Health hazards identified in our workplaces include exposure to musculoskeletal stressors, noise, coal mine dust, respirable crystalline silica, diesel particulate matter (DPM), and psychosocial hazards. We manage our exposures to potentially harmful substances and agents with internally specified occupational exposure limits (OELs) based on available scientific evidence and by implementing a program of preventative health measures and wellbeing support.

For our occupational exposures, our process to set OELs involves periodic monitoring and evaluation of scientific literature, benchmarking against peers and engagement with regulators and OEL-setting agencies.. Our approach to monitoring and reviewing our internal OELs is designed to ensure they continue to be aligned with or are stricter than applicable regulated health limits. We implement a range of exposure reduction activities designed to reduce exposures to harmful substances to as low as reasonably practicable.

We conduct periodic medical surveillance to detect signs of potential occupational illness at an early stage and assist our people through the management of illness that is a result of exposure to certain harmful substances and agents at our workplaces. Our medical surveillance program is based on local regulatory requirements and evidence-based industry best practice. The effectiveness of our exposure controls is regularly reviewed and subject to periodic audit to verify the controls are implemented and operating as designed.

The Health Global Standard is based on internationally accepted practice with requirements to identify occupational exposures with the potential to cause harm; assess the risk posed by those exposures; implement exposure controls; and where exposure cannot be immediately reduced to an acceptable level, provide personal protective equipment and undertake health surveillance.

For guidance on the process to identify and assess occupational exposures, we specifically reference:

- American Industrial Hygiene Association’s A Strategy for Assessing and Managing Occupational Exposures

- International standard ISO TR7708:1995 Air quality – Particle size fraction definitions for health-related sampling

- UK Health and Safety Executive’s Health and Safety Laboratory Methods for the Determination of Hazardous Substances (MDHS)14/4: General methods for sampling and gravimetric analysis of respirable, thoracic and inhalable aerosols

- US National Institute for Occupational Safety and Health’s Manual of Analytical Methods and the UK HSE, Methods for the Determination of Hazardous Substances

- International Atomic Energy Agency’s (IAEA) Radiation Protection and Safety of Radiation Sources: International Basic Safety Standards – Interim

- Edition General Safety Requirements Part 3. IAEA Safety Standards Series No. GSR Part 3, 2014

- European Union standards for whole-body and hand-arm vibration

-

Engagement

In line with Our Charter and our culture of care, we undertake activities to enhance the physical and mental wellbeing of our employees and contractors. This includes the provision of preventative health measures as appropriate for the location, such as vaccinations, gym facilities, onsite physiotherapy, healthy food alternatives at our worker village accommodation and a range of mental health resources including our Employee Assistance Program and peer support programs

A range of targeted health programs, such as the Better Sleep Program and Heat Management Program, are made available at many of our operated assets where there are relevant workplace issues. Workers at remote sites are provided with emergency medical care and primary health care through onsite medical facilities, with telehealth consultations available. These services are provided by qualified individuals, including paramedics, occupational health nurses and medical practitioners, as appropriate, depending on the location. In most of our remote operations, these services are accessible during and after working hours.

We continue to monitor emerging health issues and trends through our membership of industry and professional associations, informal benchmarking, industry collaboration, networking and participation in national and international conferences. We also monitor information from scientific journals and occupational health regulatory setting and advisory agencies.

-

Performance

Occupational illness

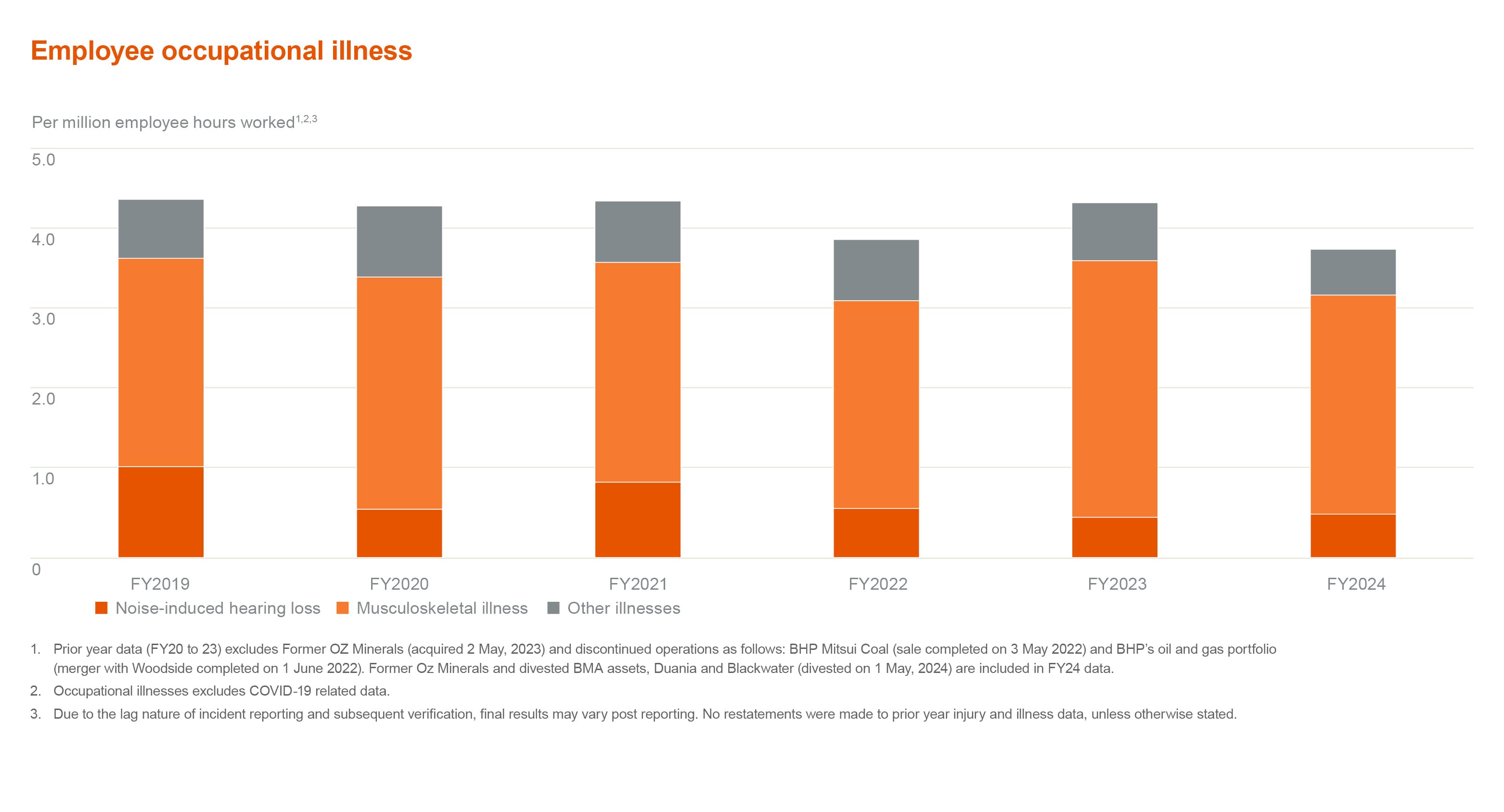

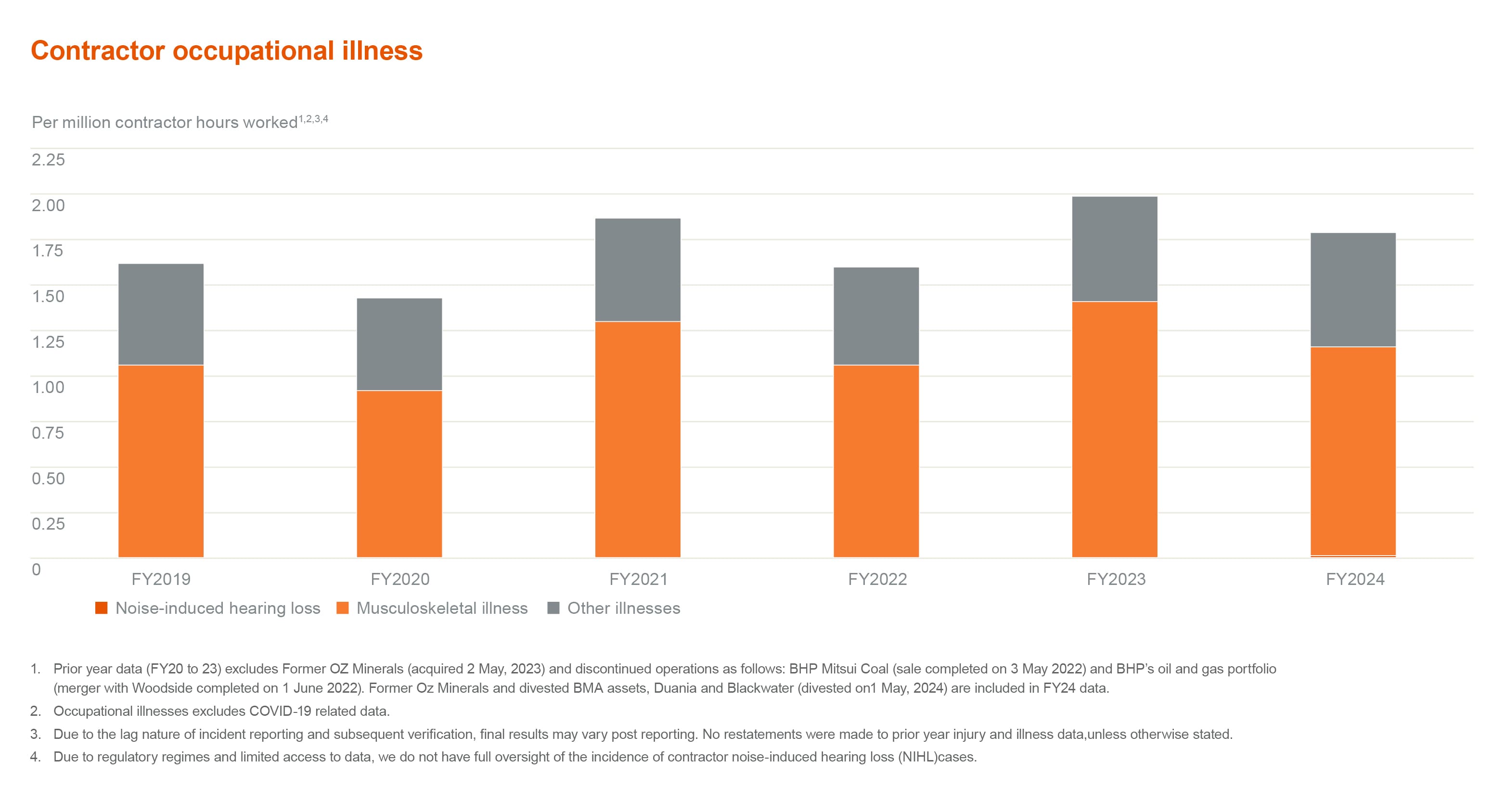

The reported occurrence of occupational illness for employees in FY2024 was 270, which was 3.77 per million hours worked. This represented a 13 per cent decrease in incidence compared with FY2023, which was 4.35 per million hours worked. For our contractor workforce, the reported occupational illness in FY2024 was 216, which was 1.79 per million hours worked, representing a 10 per cent decrease in incidence compared with FY2023, which was 1.99 per million hours worked.

Musculoskeletal illness is the predominant occupational illness category for BHP employees and contractors, representing 68 per cent of our workforce illnesses in FY2024. These conditions include damage to bones, joints, ligaments, tendons and soft tissues, caused by repetitive heavy work, muscular strain, or maintaining poor postures for extended periods of time.

Noise-induced hearing loss represents 8 per cent of occupational illnesses in FY2024. Employees and contractors exposed to noise levels above the defined workplace exposure limits in our Health Global Standard participate in hearing conservation programs, which include a periodic hearing test and hearing protection fit testing. We have established design recommendations that seek to eliminate or reduce high or prolonged noise exposures by focusing on noise source.

Occupational exposures

BHP follows the hierarchy of controls to reduce occupational exposures to as low as reasonably practicable. Our mandatory minimum performance requirements for risk management and our Risk Framework support the identification and management of occupational exposures. Where there is a potential for our employees and contractors to be exposed to chemical and physical hazards in workplace atmospheres, we implement controls intended to prevent, minimise, and/or mitigate the likelihood and severity of potential associated health impacts. These actions may include the use of respiratory protective equipment until appropriate, higher-order controls have been identified, implemented and verified to consistently reduce exposure below occupational exposure limits. Occupational exposure limits indicate the level of permissible exposure for a length of time (usually eight hours) to a chemical or physical hazard that is not likely to affect the health of a worker. Occupational exposure limits for our most material exposures are set according to the latest scientific evidence.

Exposure data in this Report in all cases is presented without considering protection from the use of personal protective equipment where required, as outlined in our Health Global Standard.

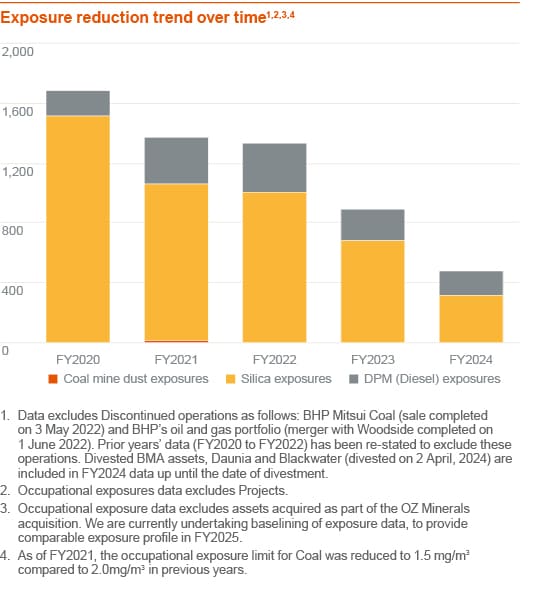

In FY2024, for our most material exposures of diesel particulate matter (DPM) and respirable silica, we had a 46 per cent reduction in the number of employees and contractors potentially exposed compared to our FY2023 exposure profile. More specifically, we have recorded a 23 per cent reduction in the number of employees and contractors with potential exposure to DPM and 54 per cent reduction in the number of employees and contractors potentially exposed to respirable crystalline silica. When exposure reduction is considered over the last six years, we have achieved a 78 per cent reduction to our most material exposures. We continue to have zero employees and contractors routinely exposed to coal mine dust above the occupational exposure limit. We are currently undertaking a baseline exposure monitoring program at the former OZ Minerals Australian assets and will provide a comparable exposure profile in FY2025.

Managing heat stress

Heat stress contributed to 4 per cent of our reported occupational illnesses in FY2024. Elevated temperatures and strenuous activity place some of our workforce at an increased risk of heat illness. High-risk work groups are identified, and a range of controls are in place to manage heat stress. In FY2024, a new heat awareness online learning module was released for workers across Minerals Australia, to provide workers with the knowledge to identify signs of heat illness and how to manage the risks associated with working in the heat. Hydration testing has also been made available at several operations with high heat risk.

Recognising climate change may exacerbate existing temperature related risks, in FY2024 we piloted an approach at Olympic Dam to better understand and quantify the potential impact of heat stress on our workforce under different future climate scenarios. Modelling was based on climate data and temperatures within the underground mine to determine potential productivity and health impacts caused by heat stress under different scenarios. The findings of this assessment will assist in the identification of additional controls that may be required to ensure our workforce can perform their roles safely under changing climatic conditions.

Coal mine dust lung disease

In FY2024, 21 cases of coal mine dust lung disease (CMDLD)1 were reported to the Workers' Compensation Regulatory Services.2 Off the 13 accepted claims in FY2024, 2 were current BHP employees, while the remaining 11 were former employees. For cases involving current employees, we offer counselling, medical support, and redeployment options where relevant. Former employees are eligible for workers’ compensation insurance and associated care is managed externally to BHP.

We have controls in place across all our relevant operated assets with the goal of ensuring none of our employees and contractors are exposed to respirable CMD above the occupational exposure limit (OEL). We continue to identify and progress projects, such as enhancing our real-time dust monitoring, to facilitate our recognition and action when the working environment may present a health hazard and seek to implement high order controls, such as engineering controls, to eliminate or reduce exposures rather than continued reliance on lower order controls, such as respiratory protection. We have observed consistent control of CMD exposures with no employees or contractors potentially exposed to CMD above the OEL since FY2021.

1 CMDLD is the name given to the lung diseases related to exposure to coal mine dust and includes coal workers’ pneumoconiosis, silicosis, mixed dust pneumoconiosis and chronic obstructive pulmonary disease.

2 Cases reported to Workers' Compensation Regulatory Services are not an indication that the CMDLD was related to work. BHP evaluates each case for work relatedness and where identified, the case will be included in occupational illness reporting.

Physical and mental health

The physical and psychological health and wellbeing of our workforce is of paramount importance as we continue to work towards enhancing the inclusivity and future-readiness of our employees and contractors. In FY2024, we continued efforts to make meaningful and positive improvement to employee health and wellbeing by building stronger relationships via our active collaborations with industry partners. We engaged with initiatives such as the ‘Minding Mining Minds’(MMM), which aims to develop tools and evidence-based models and share learnings across industry, the Building Safe and Respectful Workplaces (BSRW) which aims to help eliminate disrespectful behaviour in the resources industry including sexual harassment, bullying and racism and we have an active partnership with the Global Business Collaboration for better mental health.

Our focus internally has been on embedding our learnings. In FY2024, we embedded the BSRW principles into our global onboarding. A Global Wellness Committee was also established, bringing together asset and corporate office Wellness Committees into a global forum to collaborate on initiatives, implement strategic improvements and share learnings. The Committee aims to build mental health literacy, increase awareness and benefit overall physical and mental wellbeing, and has maintained a strong ongoing participation in global health campaigns, such as BHP Mental Health Month, RUOK day and Movember.

In FY2024, the Group Health team introduced the Women Can initiative to promote women’s physical and mental health. The Women Can initiative ran during March, aiming to lift the profile and importance of women’s health and wellbeing. Through prestart education packs, personal shares and panel discussions held with senior female leaders, including our Chief People Officer, and Group HSS Officer, BHP provided education and an opportunity for safe and impactful conversations on the importance of self-care, health screening, menopause and providing a safe and inclusive workplace. During this campaign, BHP formed a formal partnership with Menopause Friendly Australia and is working towards achieving accreditation as a menopause friendly employer where we aim to raise awareness, educate staff and engage in training and policy and process change to address womens’ health and menopause in the workplace.

Support for employees affected by family and domestic violence

Caring for our people’s safety extends beyond our operations.

BHP has a Family and Domestic Violence Assistance Program, which was updated in FY2024, that aims to provide employees with support for their health, safety, wellbeing and independence if they are experiencing family and domestic violence.

As part of the program, employees can access up to 10 days’ additional paid leave if they are affected by family and domestic violence or supporting someone who is.

Support also includes emergency accommodation, emergency financial help and access to safety and security plans. These supports consider safety measures, such as transport to and from work, changing location of work, setting up new phone numbers, screening/blocking calls and emails, and supporting access to legal advice.

Risk

When a health issue has the potential to impact the health or wellbeing of our people, we apply BHP’s Risk Framework to identify, assess and manage the risk. For more information on risk, refer to the BHP Annual Report 2024.

Reducing welding fume exposure at Olympic Dam

Our Smelter Maintenance team began collaborating with our Occupational Hygiene team in 2021 to implement improved controls with the aim of achieving significant welding fume exposure reductions.

Sustainability case studies, organisational boundary, definitions and disclaimers, and downloads

Prior year versions of some of the listed documents are available on the Past reports page.-

BHP Annual Report 2024

pdf

16192519

-

Sustainability reporting organisational boundary, definitions and disclaimers

pdf

161998

-

BHP ESG Standards and Databook 2024

xlsx

2555913

-

BHP Modern Slavery Statement 2024

pdf

4092160

-

BHP Climate Transition Action Plan 2024

pdf

8480121

-

BHP GHG Emissions Calculation Methodology 2024

pdf

1028031

-

CDP 2023 Submission Not Graded

pdf

1053064

-

Global Industry Standard on Tailings Management – Public Disclosure 2024

pdf

2809793

-

Tailings Storage Facility Policy Statement 2023

pdf

73457

-

Information for social investment partners

pdf

26113

-

Industry response to SBTI scope 3 discussion paper

-

Case studies