06 September 2022

A BHP-developed system is harnessing data from a range of existing safety systems to improve safety in light vehicles (LV) and surface mobile equipment (SME) at Western Australia Iron Ore (WAIO) mine sites.

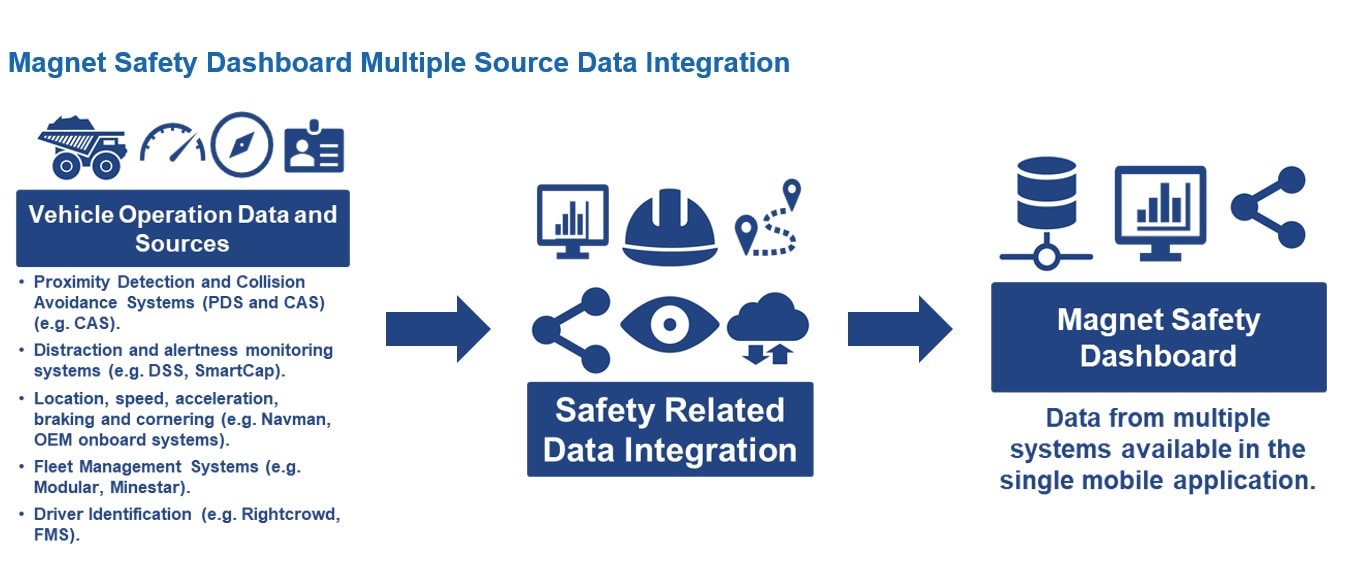

Magnet Safety Dashboard (MSD) uses existing operator and equipment monitoring systems to quickly identify potential behaviours or job factors that might increase the likelihood of safety events occurring (‘at risk’ scenarios). Operations have historically used different hardware and software systems in isolation. MSD was developed to address integration potential between existing systems providing population-sized data sets on driver/operator behaviour.

Events and hazards associated with LVs and SME can occur frequently at BHP, so the ability to quickly understand and influence human and job factors, which could contribute to safe outcomes, supports leaders to manage risk more holistically.

MSD harnesses a range of data from collision avoidance, distraction and alertness monitoring and fleet management systems, including location, speed, acceleration, braking and cornering. All selected information is monitored and assessed from a central location, which allows immediate access for relevant employees and medium-to long-term trend analysis.

Over 800,000 metrics from more than 20,000 devices, using 300 instances of 60-plus data points, are collected.

Leaders are alerted if hardware, software and network controls are not operating as expected, while team members are alerted if acute intervention is required (where it is possible to achieve).

The system has also created efficient ways to record and display recommended response actions where chronic patterns are present.

This accurate and timely notification of driver behaviour events, trends and hot spots requiring improvement has increased awareness and, in the Yandi mine site, resulted in reductions to the frequency of fatigue, distraction, error and non-compliance events.

The Magnet Safety Dashboard program at Yandi Mine Site’s has contributed to a 58 per cent reduction in overall reported vehicle events (December 2020 to April 2021) and a 70 per cent reduction in reported speeding events (October 2020 to April 2021). Following the programs positive results and learning at the Yandi mine site, an MSD pilot will be implemented across all WAIO mine sites.

Get the latest BHP news alerts, straight to your inbox

Get BHP news first. Stay in touch with our latest updates, investor news and media releases.