19 agosto 2025

Extended reality (XR), encompassing augmented reality, virtual reality (VR) and mixed reality, is changing the way many industries provide training, connect remote teams, and understand the ‘context of work’. XR is being used by industries to help identify factors that facilitate safe work practices and challenges and opportunities for improving the way work is done.

Through wearable XR technology, such as Smart Helmets (helmets fitted with a microphone and camera), digital information can be overlayed onto the real world or merged with it, and users can be immersed into a complete 360-degree digital experience.

At BHP, we are exploring utilising XR technologies such as Smart Helmets, VR, mixed reality and augmented reality to enhance our safety culture and work practices.

Connecting leaders and coaches with our frontline people

As part of our global Field Leadership Program, our leaders spend time in the field engaging with our people on the frontline, to foster a culture of care through ‘felt leadership’, and promote learning and improvement by seeking to understand the reality of work.

Logistics such as transportation, scheduling and physical restrictions can present challenges for meaningful and regular field leadership.

Recognising this, BHP’s Mobility and Development and Workplace Technology teams tested wearable XR technology to enable remote field leadership, including coaching, for activities such as forklift inspections. In one part of our business, this is a routine maintenance task used across 19 sites to help ensure forklifts are maintained and operated safely.

In this example, the forklift operator used a Smart Helmet with hands-free voice control, while the BHP Operating System (BOS) coach and team members located across Adelaide and Brisbane viewed the real-time feed, gaining insights directly from the operator’s perspective. By observing the operator’s working environment and the steps undertaken during the inspection, the coach and team members identified opportunities to strengthen the risk controls and improve the work procedure to make it safer to perform the work.

This is one example of how XR technology can enable our people to learn about work from the person doing it and closest to the risks. At the same time, connection through ‘felt leadership’ and collaboration and connection are reinforced. This is also a great example of how we live our BHP values as we ‘seek better ways’ to learn and improve and ‘make a difference’ through connection and collaboration across geographical divides.

Smart Helmets are now available as technology-supported equipment to enable remote field leadership and promote safe operational outcomes

Enhancing safety training at Olympic Dam

We have also been trialling XR technology to supplement safety training at Olympic Dam to enhance hazard awareness and improve understanding of the concept of a hazard as a source of potentially ‘damaging energy’ within our surface and underground operations.

Understanding ‘damaging energies’ provides a different way to identify how a person may be seriously harmed or killed, as they are present or created during interactions between people, equipment and the work environment as part of everyday work. Examples include vehicular, gravitational, machine, object, human, chemical, thermal, electrical, and noise-related energies.

The Asset Training team at Olympic Dam released our first two VR modules using VR headsets, allowing our people to practise safely in a virtual environment.

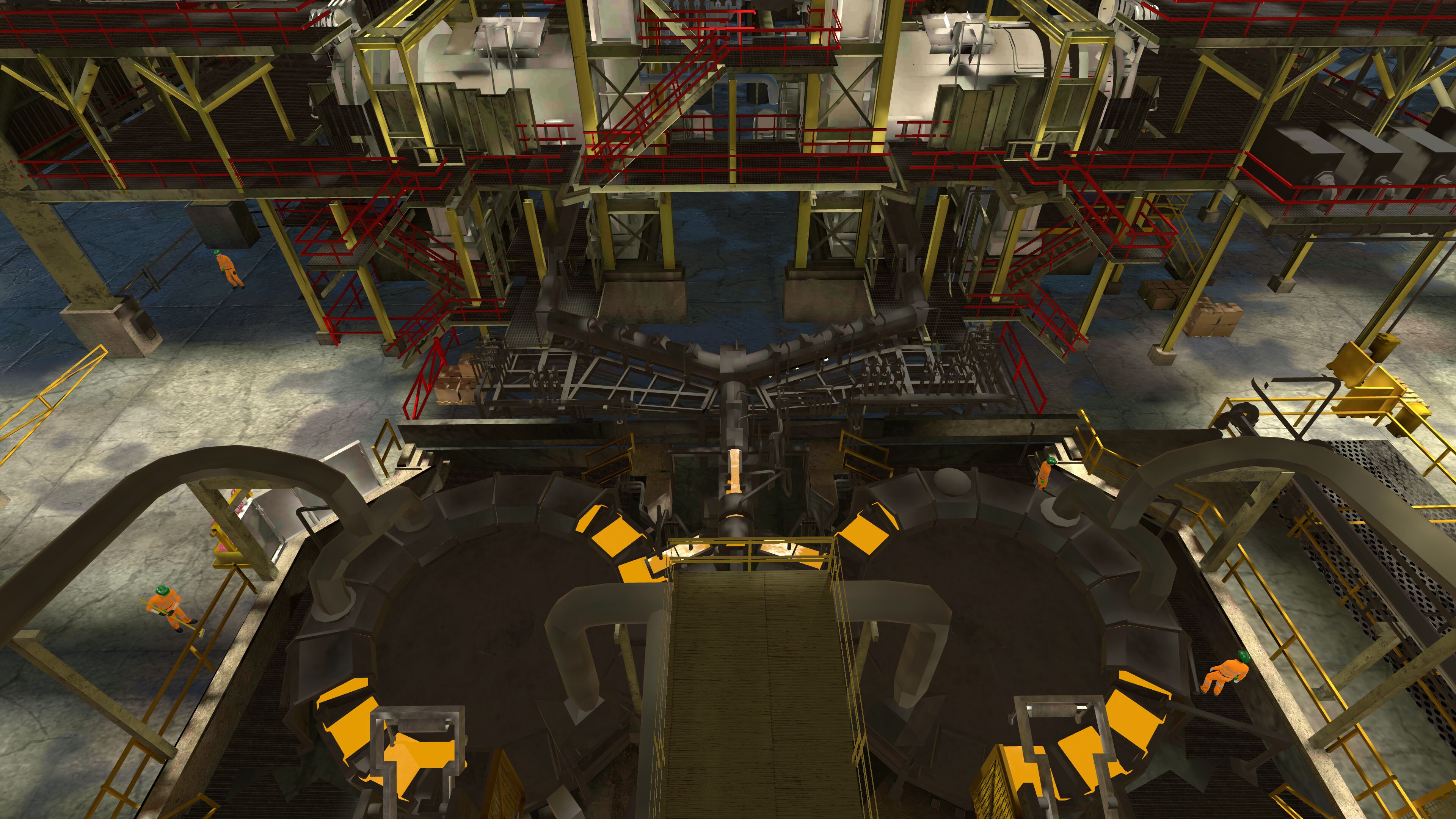

The first module explores damaging energies/hazards in the smelter, while the second focuses on the 420 Plat workshop, located 420 metres underground.

Image caption: The first Damaging Energies VR module which explores hazards in the casting pad in Olympic Dam’s smelter.

Image caption: The second Damaging Energies VR module which explores hazards found in and around the underground Mine Maintenance workshop.

The advantages of this type of training include allowing people to practise skills and decision-making, and ‘fail safely’ in a dynamic, immersive and controlled environment.

Feedback on the XR technology trials showed an overall increase in the average score used to measure the quality of training material.

These initial use cases for XR technology are helping to unlock further applications across BHP as we continue to focus on:

- proactively integrating safety in the way work is performed by using the BHP Operating System (BOS)

- striving to improve the quality of our global Field Leadership Program engagements

- uplifting safety leadership capability across our organisation